Hey there, tech enthusiasts, students, and curious minds! Welcome to my electronics blog, where we dive into the fascinating world of components that power our gadgets.

Today, we’re talking about thermistor tiny but mighty devices that play a huge role in temperature measurement and control.

Whether you’re building a smart device, tinkering with circuits, or just love learning about electronics, this guide is for you.

What is Thermistor?

A thermistor (thermal resistor) is a type of resistor whose resistance changes significantly with temperature. Unlike standard resistors, thermistors are highly sensitive to temperature variations, making them ideal for temperature sensing and control applications

There are two main types of thermistors:

- NTC Thermistors (Negative Temperature Coefficient): As the temperature goes up, their resistance goes down. Think of them as the go-to choice for precise temperature measurements.

-

PTC Thermistors (Positive Temperature Coefficient): As the temperature rises, their resistance increases. These are great for things like protecting circuits from overheating.

Thermistors are small, affordable, and super versatile, which is why you’ll find them in everything from your smartphone to medical equipment.

How Does a Thermistor Work?

Let’s get to the heart of it: how do these little components do their magic? Thermistors work because their resistance is tied to temperature. Here’s the breakdown:

The Working Principle

-

NTC Thermistors: At cooler temperatures, their resistance is high. As things heat up, the resistance drops in a predictable (but nonlinear) way. This makes them awesome for measuring temperature accurately.

-

PTC Thermistors: The opposite happens like resistance climbs as the temperature rises. This makes them ideal for protecting circuits or controlling heating elements.

The science behind it? For NTC thermistors, it’s all about the Steinhart-Hart equation, which maps resistance to temperature. For PTC thermistors, it’s about the material’s unique properties (like barium titanate) that cause resistance to spike with heat.

How Thermistor Works in a Circuit

Picture this:

-

You connect a thermistor in a circuit.

-

As the temperature changes, the thermistor’s resistance shifts.

-

This change tweaks the voltage or current in the circuit.

-

A microcontroller or display reads this signal and translates it into a temperature reading or triggers an action (like turning on a fan).

Think of a thermistor as a temperature detective, constantly reporting changes to keep devices safe and efficient.

Thermistor as Temperature Sensors

Thermistors shine as temperature sensors because they’re sensitive, fast, and accurate. Here’s where you’ll find them saving the day:

-

Medical Devices: From digital thermometers to wearable health trackers, thermistors monitor body temperature with pinpoint precision.

-

HVAC Systems: Your air conditioner or heater relies on thermistors to keep your home comfy.

-

Automotive: Thermistors check coolant, air intake, or battery temps in cars, especially electric vehicles.

-

Consumer Electronics: They prevent your laptop or phone from overheating.

-

Industrial Applications: Thermistors ensure food processing, manufacturing, and environmental systems stay in check.

With a temperature range of -50°C to 300°C, thermistors are compact powerhouses that fit almost anywhere.

Thermistor Symbol and Circuit Diagram

Let’s talk visuals! In circuit diagrams, thermistors have a distinct symbol to show they’re temperature-sensitive:

-

Thermistor Symbol: It looks like a resistor (a zigzag line) with a little “t” or “θ” (theta) nearby to scream “I’m temperature-sensitive!”

Text version: —-/\/\/\—- t -

NTC vs. PTC Symbols: Some diagrams add a curve or label (“NTC” or “PTC”) to show the type.

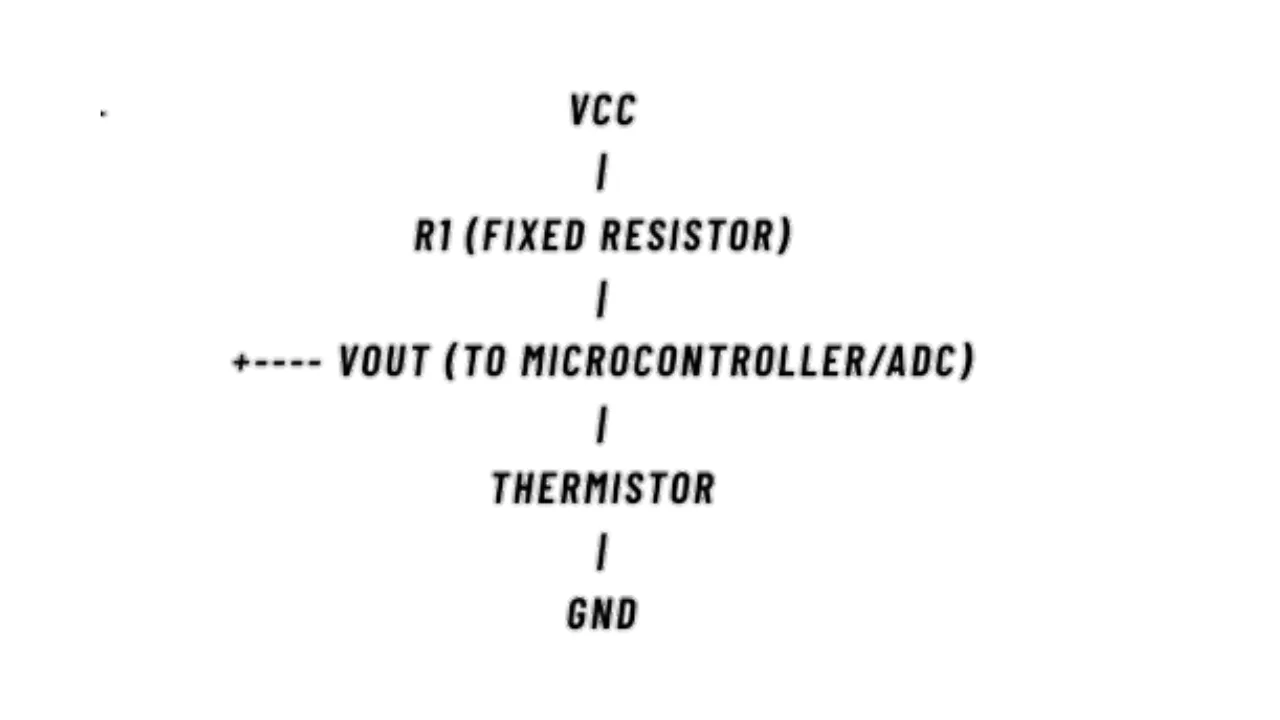

Simple Thermistor Circuit

Here’s a quick look at a common setup—a voltage divider circuit:

What’s happening here? The thermistor and a fixed resistor (R1) split the voltage from Vcc. As the thermistor’s resistance changes with temperature, the voltage at Vout shifts. A microcontroller reads this voltage to calculate the temperature. Simple, yet powerful!

Thermistor Manufacturing in India

India is stepping up its game in electronics, and thermistor manufacturing is no exception. Thanks to initiatives like Make in India, the country is becoming a hub for these tiny temperature sensors. Let’s explore:

How Thermistors Are Made

-

Materials:

NTC thermistors use ceramic materials like manganese, nickel, or cobalt oxides. PTC thermistors often use barium titanate. India sources some materials locally but may import high-purity ones. -

Process:

-

Mix metal oxides and shape them into beads, discs, or chips.

-

Sinter them at high temperatures to form the thermistor.

-

Add conductive electrodes for circuit connections.

-

Coat with epoxy or glass for durability.

-

Test rigorously for accuracy and reliability.

-

-

Key Players:

Big names like Murata, Honeywell, and Indian companies like Bharat Electronics Limited (BEL) are producing thermistors for local and global markets. -

Applications in India:

From electric vehicles to IoT devices, Indian-made thermistors are everywhere.

Types of Thermistors and Their Applications

Let’s compare the two thermistor types and see where they shine:

|

Type |

Characteristics |

Applications |

|---|---|---|

|

NTC Thermistor |

Resistance decreases as temperature rises |

Temperature sensors, medical devices |

|

PTC Thermistor |

Resistance increases as temperature rises |

Overcurrent protection, heaters |

Thermistor Applications

-

Battery Management: Thermistors keep batteries in electric vehicles and laptops safe by monitoring temperature.

-

Home Appliances: Your fridge, microwave, or coffee maker uses thermistors to stay at the right temp.

-

Environmental Monitoring: Weather stations and climate research rely on thermistors for accurate data.

Why Thermistors are Important

Thermistors are a favorite for a reason:

-

Super Sensitive: They catch even tiny temperature changes.

-

Tiny Size: Perfect for small devices like wearables.

-

Budget-Friendly: Affordable for mass production.

-

Wide Range: Works in freezing cold or scorching heat.

Limitations of Thermistor to Keep in Mind

No component is perfect, right? Here’s where thermistors have some quirks:

-

Nonlinear Response: Their resistance doesn’t change in a straight line, so calibration is needed.

-

Temperature Limits: They’re not great for super-high temperatures (thermocouples might be better).

-

Fragility: Ceramic thermistors can break in rough environments.

The Future of Thermistors

Thermistors are getting even cooler with tech advancements:

-

IoT Integration: Smart thermistors for real-time data in connected devices.

-

Smaller Sizes: Tiny thermistors for wearables and medical implants.

-

Eco-Friendly Materials: Greener manufacturing to save the planet.

-

AI and Automation: Smarter thermistors for smart homes and self-driving cars.

Conclusion

Thermistors are the unsung heroes of temperature sensing and control. From keeping your phone cool to ensuring medical devices are accurate, they’re everywhere!

In India, thermistor manufacturing is booming, powered by demand and innovation. Whether you’re a student, engineer, or tech lover, understanding thermistors opens the door to exciting projects.

I hope this guide made thermistors crystal clear and sparked some ideas for your next electronics adventure. Got questions or want to share your thermistor projects? Drop a comment below, and let’s keep the conversation going!

If you liked this article, don’t forget to check back daily!

I regularly post updates on the latest trends in electronics, new product launches, tech innovations, industry news, and updates from electronic companies.

Follow the blog or bookmark this site to stay ahead in the world of electronics!

Feel free to share this article on your favorite social media platforms!